Cellophane Paper

2022-06-14 13:04 Beauty & Well being Satna 480 views Reference: 1107Location: Satna

Price: Contact us

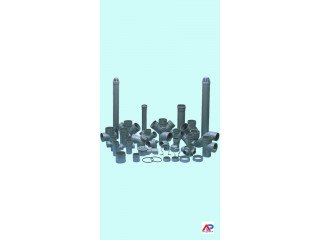

What is Filter Paper?

The filter paper for laboratory use is one of the common lab consumables. It is normally round in shape and made from cotton fiber and used to filter components. The functional principle of the filter paper is separating the substances through them. They are normally made from fiber, which is the reason that there are keyholes on them. The keyholes resist the big solid particles and provide pathways for the liquid particles. And the most common usage for a filter paper nowadays is as a Printing Filter Paper.

The different kinds of filter papers having different characters are made by different technics. So, what are the main factors in the filter paper selection? There exist four: hardness, capacity, filtration efficiency, and applicability.

Filter Paper Structure

The filter paper is directional. The front side of the filter paper has loose fibers; the mesh surface of the filter paper has tight fibers. The front pores are in the shape of a bell mouth, and the pores become smaller along with the thickness of the filter paper. The thickness of the filter paper is about 0.350.5mm, and the particle size of dust particles varies from ranging from a few microns to tens of microns.

Filter paper filtration not only has the function of a screen but also has the function of deep filtration; the side magnification shows that the filter paper is a multi-layer structure. The front of the filter paper should face the direction of airflow, the screen surface should be in the direction of the gas flow. Color lines are drawn on the screen surface to facilitate user identification and prevent mistakes; if the front and back directions are wrong, the filter element is in use, and dust is stored. Ability is reduced by 30%.

As for different materials for paper or film, there is a widely used material that has to be mentioned. It is Cellophane Paper. What is Cellophane or Cello? Cellophane wrap has long been used to encase edible treats like lollies, nuts and baked goodies, however Cellophane wrapping is especially used in floristry to wrap fresh and artificial .

Originally marketed as packaging material in America in 1924, cellophane wrap was the most popular choice of film until the introduction of Polypropylene (PP) in the 1960s. PP quickly became the preferred clear packaging film choice mainly due to its low manufacturing costs and high resistance to many chemicals. Therefore, when referring to cellophane wrap it would encompass both true cellophane (made of wood pulp and cotton) and BOPP (bi-axially orientated polypropylene which means that the PP has been shaped).

What's more, more and more materials are used for different purposes nowadays, such as Non Woven Fabric, Wax Paper, Bopp Film for Flowers Packing and so on.